If you’ve ever wondered what a solenoid valve is and how it works, Fluid Controls is here to explain all. Read on to find out how a solenoid valve works, as well as an overview of some of our premium solenoid valve types from Parker.

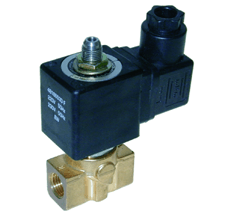

A solenoid valve, otherwise known as an electrically-operated valve, is an automatic valve that removes the need for an engineer to operate a valve manually. Solenoids operate using an electromagnetic solenoid coil to change the state of a valve from open to closed, or vice-versa.

If the solenoid valve is ‘normally closed’, when the coil is energised, the valve gets lifted open by the electromagnetic force produced by the coil.

For correct and accurate control functioning, solenoid control valves must be configured and selected according to their special purpose. The most important parameters for selecting a solenoid control valve are the Kv value (given in cubic meters per hour) and the application’s pressure range.

The lower the valve’s orifice, or the stronger the coil, the higher the pressure the valve can shut-off. On the basis of the calculated Kv value, and the pressure range of the planned application, a correspondingly appropriate valve type and its required orifice can be determined.

Solenoid valves can be used in any application where a clean (non-viscous) process media, such as very clean liquids/gases/light oils, need to be controlled. Simple on/off valves are the most popular as many process lines only need flow or no flow. Solenoid valves can be used in factories where compressed air is not available.

They can also be used in place of larger valves, such as electrically actuated ball valves, but without taking up anywhere near as much space. Operation is also much quicker than other valve technologies. Other solenoid operated valves use a more advanced technology. That means they can be used to proportionally control flow or pressure depending on a varying input signal.

This is where another component further downstream needs a specific pressure or flow to maintain the correct working conditions. Most common input signal used would be a 4-20mA loop signal which most factories will have at their disposal usually controlled by a PLC or similar system.

Solenoid valves benefit a range of applications. Read our blog post on solenoid valve benefits to find out more.

Mounting Solutions:

• Pipe

• Sub-base

• NAMUR

• Banjo

• CETOP

• ISO

Speak to a Fluid Controls adviser today about all your Solenoid Valve requirements by calling +44 (0) 118 970 2060 or email fluid@fluidcontrols.co.uk.