Push-fit fittings are useful components in many applications, which make assembly and maintenance extremely simple. Ideal for use in potable water, plumbing, water heaters and hydronic heating systems, push-fit fittings can be used in both new residential and commercial construction. How do you remove push-fit fittings, though? To find out, read this helpful guide from Fluid Controls.

Often referred to as a push-to-connect fitting or a quick-connect fitting, a push-fit fitting is a type of plumbing or pipe fitting that allows for quick and simple installation without the need for special tools or equipment.

Push-fit fittings are designed to connect pipes of various materials, like PVC, CPVC, PEX and copper. These fittings consist of a body made from a variety of materials, with an O-ring or sealing gasket and a steel gripping ring. The pipe is inserted into the fitting and the gripping ring is pushed over the pipe to secure it in place. The O-ring provides a watertight seal to prevent any liquids from getting in or out.

So, now you know what a push-fit fitting is and how it’s attached, it’s important to know how to disconnect plastic pipe fittings. Here’s how:

Push-fit fittings are used in a wide range of applications and industries, including:

Push-fit fittings are most commonly used in residential and commercial plumbing applications for connecting pipes. They’re used to connect water supply lines, waste lines, and gas lines.

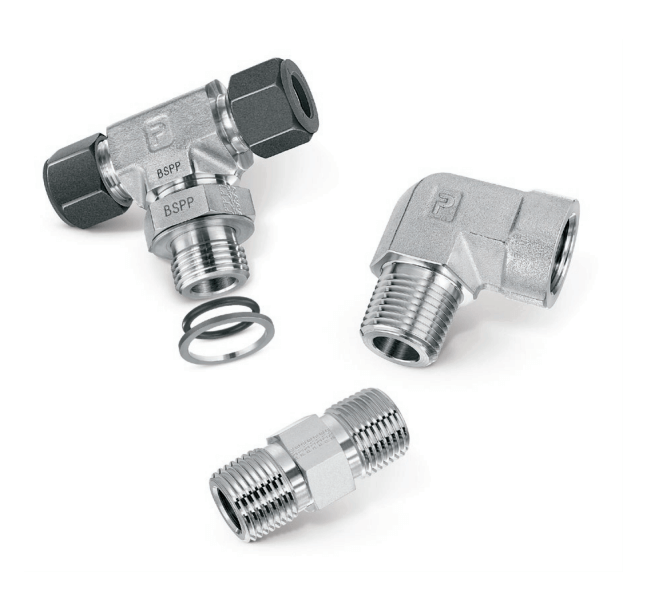

Push-fit fittings are used in a variety of industrial applications, including compressed air systems, hydraulic systems, and pneumatic systems. Push-fit fittings are ideal wherever connections between pipes and fittings are needed in these applications.

Heating and cooling systems also use push-fit fittings. They’re used in heating, ventilation and air conditioning (HVAC) systems as well as floor heating systems. They connect pipes that carry hot and cold water.

You will also find push-fit fittings used in many DIY projects. They’re used for various home improvement projects, such as installing a sink or shower.

Push-fit fittings are so popular among a wide range of industries and applications due to their many benefits. These include:

As fittings suppliers, Fluid Controls stocks an extensive range of fittings to suit any application. We can supply a broad range of premium fittings, ranging from a-lok and buttweld pipe fittings from Parker to sanitary pipe fittings from Bürkert and high-purity fittings from Parker’s Vacuseal range. We also supply push-in fittings from Legris and Norgren.

If you’d like to find out more about our range of fittings, don’t hesitate to contact us today at +44(0)118 970 2060, or email us at fluid@fluidcontrols.co.uk.