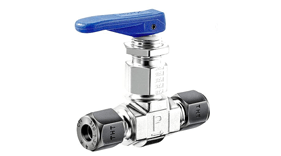

Needle Valves

As part of our valves range, Fluid Controls stocks high-performance stainless steel needle valves from industry-leading manufacturers, Parker. Needle valves are used to control flow in water and gas applications, performing shut-off and regulating operations. These control valves are often sought after by businesses within the process industry for accurately controlling flow rates of liquids and gasses, preferably for low flow rates and large pressure drops from the valve inlet to outlet.

Needle control valves

Our high-quality needle control valves can be used within delicate gauges which might be damaged by sudden surges of fluid under pressure. Additionally, needle valves can be used in scenarios where flow must be halted gradually or precise adjustments of flow are required and small flow rates are desired. Most stainless steel needle valves we stock here at Fluid Controls feature tapered pins which gradually open a space for fine control of flow. This can be controlled by use of a spindle. Stainless steel needle valves such as those manufactured by Parker feature high-pressure capabilities and relatively small orifices with a long, tapered seat. They also feature needle-shaped plungers on the end of a screw that fits near perfectly. As the screw is turned and the plunger retracts, flow is enabled through the needle valve.

Water needle valves

Frequently sought after for modulating the flow of water, most standard needle control valves, such as those manufactured from brass, are used within drinking water applications. However, for treating seawater and distilled water, we advise choosing stainless steel needle valves for their corrosion resistance qualities. As such, Fluid Controls often supplies business with water treatment applications which require optional regulation, such as those within the wastewater industry.

Gas needle valves

Along with treating various liquid applications, needle valves are frequently used for controlling the flow of clean gases. Gas piping and booster systems tend to utilise neede control valves made from brass. While applications within the oil & gas benefit from stainless steel needle valves due to their higher resistance capabilities.

Stainless steel needle valves from Parker

Our high-pressure stainless steel needle valves from Parker are designed for positive leak tight shut-off and regulating water and gas process instrumentation applications. Available in a variety of styles, port sizes, temperature capabilities and pressures, Parker needle valves provide operators with maximum flexibility when designing tubing or piping systems. Stainless steel needle valves also feature superior chemical resistance capabilities, meaning they can be applied to even the most challenging media types. Additionally, our stainless steel needle valves can withstand the highest temperatures and pressures ensuring durability for aggressive and corrosive operating conditions.

Here at Fluid Controls, we stock a wide range of needle control valves from Parker such as:

- Parker HV Series Needle Valves

- Parker PV Series Needle Valves

- Parker U Series Needle Valves

- Parker VQ Series Needle Valves

- Parker NP6 Series Needle Valves

- Parker SN6 Series Needle Valves

Parker HV series needle valves

Parker’s HV series needle valve is a rotary disc valve with a robust knob manual operator. The valve is surface mounted with side ports, and three-position, all ports blocked, spring return, versions are available. Pressure: 0 to 150 PSIG. Port sizes: 1/4 to 1/2.

Parker PV series needle valves

Parker PV series needle valves come as either rising plug or gauge/root valves and are available with a variety of seat and seal materials. They have screwed bonnet designs featuring bonnet lock plates. These needle valves provide a straight-through flow path in two orifice sizes, utilising a non-wetted upper stem and a non-rotating lower stem in conjunction with a tapered seat for positive shut-off and long seat life, even in particulate media.

Parker U series needle valves

Parker U series bonnet needle valves have been engineered for use at pressures up to 6,000 psi (414 bar) and temperatures as high as 1,200 °F (649 °C). A non-rotating lower stem helps to extend packing life by removing rotation from the packing area. Stem packing below the threads isolates the thread lubricant from the flow, ensuring adequate lubrication regardless of the media.

Parker VQ series needle valves

Parker VQ series needle valves are the right combination of performance and value for manual or pneumatic on-off control in moderate pressure and temperature applications. The manual version employs a toggle handle for quick action at pressures up to 300 psi (21 bar). Compact double-acting, normally closed, and normally open pneumatically actuated versions of this valve are ideal for automatic control at pressures up to 600 psi (41 bar).

Parker NP6 series needle valves

Parker NP6 needle valves are designed with packing below the stem threads and a two-piece stem. The packing below the threads protects the flow stream from thread lubricant contamination or washout and also protects the stem threads from potentially damaging effects of the media. The two-piece stem produces a non-rotating lower stem for superior, repeatable sealing and reduced packing wear.

Parker SN6 series needle valves

Parker compact SN6 needle valves provide shut-off and coarse regulation of liquids and gases utilised in process and instrumentation applications. These rugged valves are manufactured from stainless steel bar stock and feature integral bonnet designs with packing above the stem threads.

Parker V series needle valves

Parker V series needle valves are designed for positive leak tight shut-off and regulation of fluids in process, power, and instrumentation applications. With a wide variety of port sizes and styles, temperature capabilities ranging from -65 °F to 450 °F (-54 °C to 232 °C) and pressures to 5000 psi (345 bar), V Series Needle Valves provide the utmost in flexibility when designing miniaturised tubing or piping systems.

Buy stainless steel needle valves

To discuss your needle valve requirements, call Fluid Controls today on 0118 970 2060, email fluid@fluidcontrols.co.uk or complete our contact form and our team will help match a needle valve to suit your water and gas application.