Modular systems

Fluid Controls supplies a comprehensive range of Modular Systems from Parker Hannifin. From the multi-functional Parker R-Max, to the flexible Parker Intraflow series of fittings, and the breakthrough Close Coupled Instrument Mounting System (CCIMS).

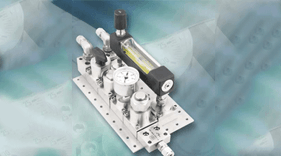

Parker R-Max

The Parker R-max™ is a multi-functional system capable of integrating both stream switching and filtering into one unique compact assembly. The system is designed to control both gases and liquids in analytical systems ranging from vacuum to 500 psig (34 bar) while requiring only 40 psig (3 bar) actuating air pressure. The system was engineered with a focus on improved product reliability and reduced cost of ownership.

The Parker R-max™ Stream Switching System utilises state-of-the-art surface mount technology to reduce leak paths, internal volume, and dead volume. With surface mounting, system components may be easily removed and replaced without breaking process connections. In addition, the Parker R-max™ system utilises an internal self-purging outlet header to eliminate the need for an additional outlet loop.

Parker Intraflow

Parker IntraFlow™ fittings provide maximum flexibility with minimal space requirements. All flowpaths, regardless of direction, are maintained on a single plane within the system as there are no lower level manifold blocks required. Contiguous fitting flow paths are intra-connected with slip fit pressure connectors, while a threaded pegboard provides connection force and rigidity when fittings are mounted with cap screws.

The system size is reduced by as much as 75% when compared with conventionally plumbed systems, drastically reducing panel space, internal volume and purge times. With the Parker Intraflow, Complex system assembly was never easier. No tube benders or cutters required, and no welding. All that’s needed to assemble it is a 5/32” hex head wrench.

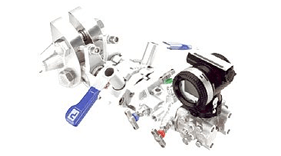

Parker CCIMS

Parker Hannifin’s response to the constant demand for higher performance in flow measurement is the introduction of a breakthrough in process control: Close Coupled Instrument Mounting System (CCIMS). Providing a radical and standardised solution for direct-mounting differential pressure transmitters to piping flanges.

Parker CCIMS supports the direct or close coupled connection of one of the most common types of process instruments – differential pressure (DP) transmitters – to process pipework. CCIMS combines an instrument manifold and a pipe interface (including isolation valves) and provides a standard means of connecting instruments with huge cost, performance and safety advantages.